Blog

What Is an Alternator? How Does It Work?

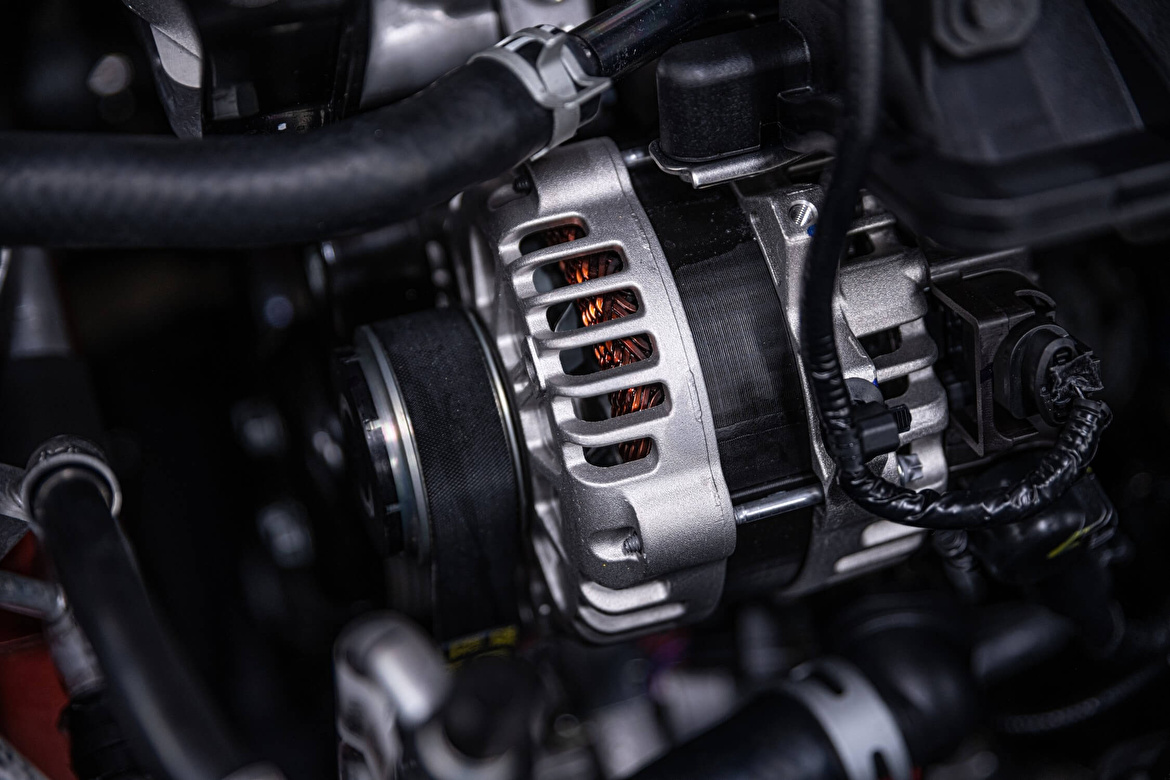

The alternator is a fundamental component in vehicles, responsible for generating electrical energy. As long as the engine is running, it powers the vehicle’s electrical systems and charges the battery. In simple terms, an alternator is a type of generator that converts mechanical energy from the engine into electrical energy.

In vehicles with internal combustion engines, the energy required to operate electrical systems—such as headlights, the radio, air conditioning, and wipers—is produced by the alternator. It activates as soon as the engine starts and continuously supplies electricity. This ensures both battery charging and uninterrupted power for onboard systems.

The alternator is the backbone of the vehicle’s electrical infrastructure and has a direct impact on driving safety. Ensuring that it functions properly is essential for the reliable operation of your vehicle.

What Does an Alternator Do?

The alternator acts as a generator that powers the car's electrical systems and recharges the battery. When the engine is off, power comes from the battery. Once the engine starts, the alternator takes over. Its main functions include:

- Powering the Electrical System:

Supplies electricity to power the vehicle’s electronics such as lights, radio, and dashboard systems. - Charging the Battery:

Recharges the battery while the engine is running, ensuring sufficient energy for the next engine start. - Regulating Electrical Output:

Uses a voltage regulator to maintain a consistent output, regardless of engine speed, to prevent damage to electrical components.

How Does an Alternator Work?

The alternator operates on the principle of electromagnetic induction. It transforms mechanical energy into electrical energy using a moving magnetic field and a stationary conductor.

Here's how it works:

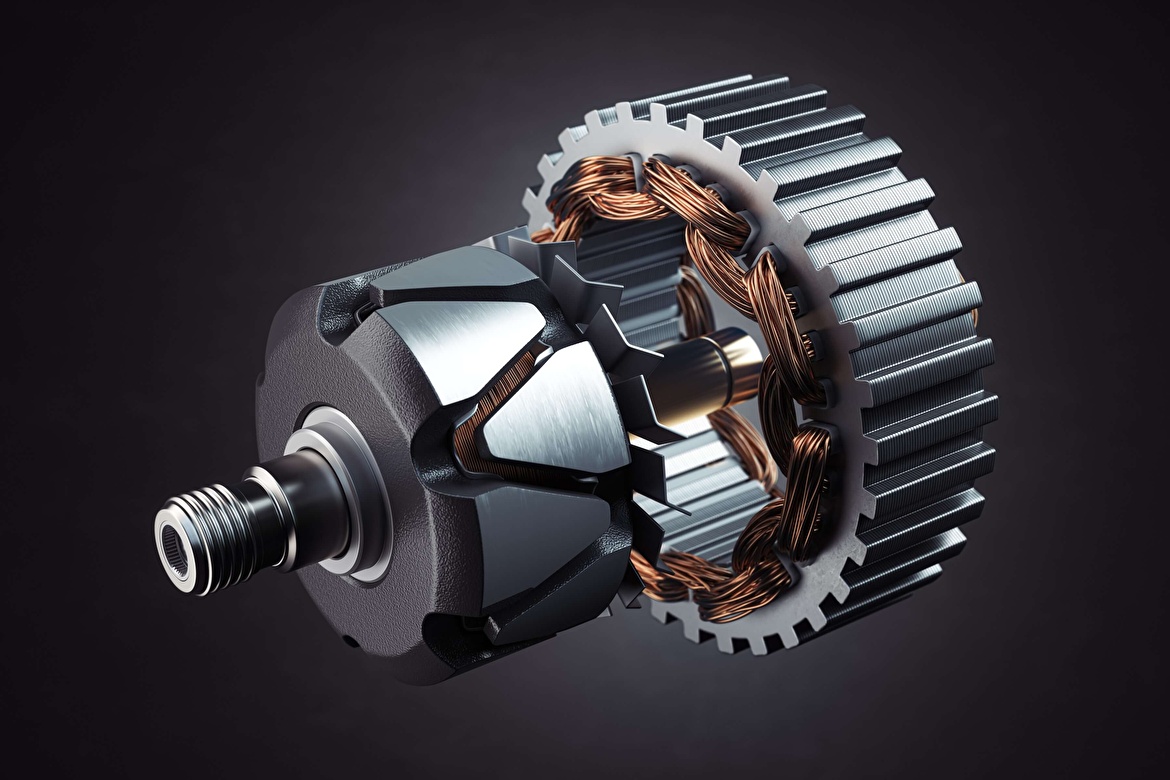

1. Mechanical Energy Conversion

- The engine’s crankshaft turns a belt that drives the alternator.

- This mechanical energy causes the rotor inside the alternator to spin.

2. Magnetic Field Generation

- The rotor contains an electromagnet that produces a magnetic field.

- As it spins inside the stator (a set of stationary coils), it induces an electrical current.

3. AC Electricity Production

- The stator generates alternating current (AC) electricity.

4. Conversion to DC Electricity

- Since vehicle systems operate on direct current (DC), a diode rectifier converts AC into DC.

5. Voltage Regulation

- As voltage output varies with engine speed, a voltage regulator stabilizes the output to protect the vehicle’s electronics.

Main Components of an Alternator

- Rotor: The rotating component that creates a magnetic field necessary for electricity generation.

- Stator: Stationary coils that generate electricity through electromagnetic induction.

- Diode Rectifier: Converts AC output to DC for compatibility with vehicle systems.

- Voltage Regulator: Keeps voltage levels stable and safe.

- Drive Belt: Transfers mechanical energy from the engine to the alternator.

Signs and Symptoms of a Faulty Alternator

An alternator malfunction can affect your entire electrical system. Common symptoms include:

- Battery Warning Light:

If the battery icon lights up on your dashboard, it could indicate the alternator isn’t charging the battery. - Electrical Failures:

Dimming headlights, malfunctioning radio or A/C may signal alternator issues. - Battery Drain:

A weak or dead battery could mean the alternator isn’t providing enough charge. - Engine Fails to Start:

If the alternator completely fails, the engine may not start at all. - Unusual Noises:

A faulty belt or worn-out bearing can cause squealing or grinding noises from the engine bay.

Common Causes of Alternator Failure

- Broken or Loose Drive Belt: Prevents mechanical energy from reaching the alternator.

- Diode Malfunction: Faulty diodes can cause inconsistent or low voltage output.

- Voltage Regulator Failure: May lead to undercharging or overcharging the system.

- Wear and Tear: Over time, internal components degrade, reducing performance.

Maintenance and Repair Tips

Routine alternator maintenance helps prevent unexpected breakdowns:

- Check the Belt:

Inspect for wear or slack regularly and replace when needed. - Monitor Electrical Performance:

Keep an eye on dashboard lights and system behavior. Have the regulator and diodes tested during service checks. - Clean Air Vents:

Ensure the alternator’s ventilation channels are clear of dust and debris. - Professional Servicing:

If performance drops, have the alternator inspected and serviced by certified technicians.

Repair Costs and Solutions

The cost of alternator repairs depends on the nature of the problem.

- Minor repairs like belt replacement are affordable.

- Replacing a faulty alternator entirely can be more expensive but is sometimes necessary for safety and performance.

Why the Alternator Matters

As a key component of your vehicle’s electrical system and battery charging mechanism, a properly functioning alternator enhances performance and prevents breakdowns. Addressing signs of failure early on can help avoid more costly damage down the line. Regular maintenance and correct usage will prolong the alternator’s lifespan and ensure optimal reliability.

Professional Maintenance with DRD Fleet Leasing

At DRD Fleet Leasing, we understand how vital electrical system integrity is for corporate fleet efficiency. That’s why we offer professional maintenance and technical support across our entire fleet. With our extensive service network and expert team, we ensure your vehicles are always performing at their best.

Let us handle the technical details click here to get a custom offer and discover how DRD Fleet Leasing can keep your operations running smoothly.